October 23 – November 16, 2014.

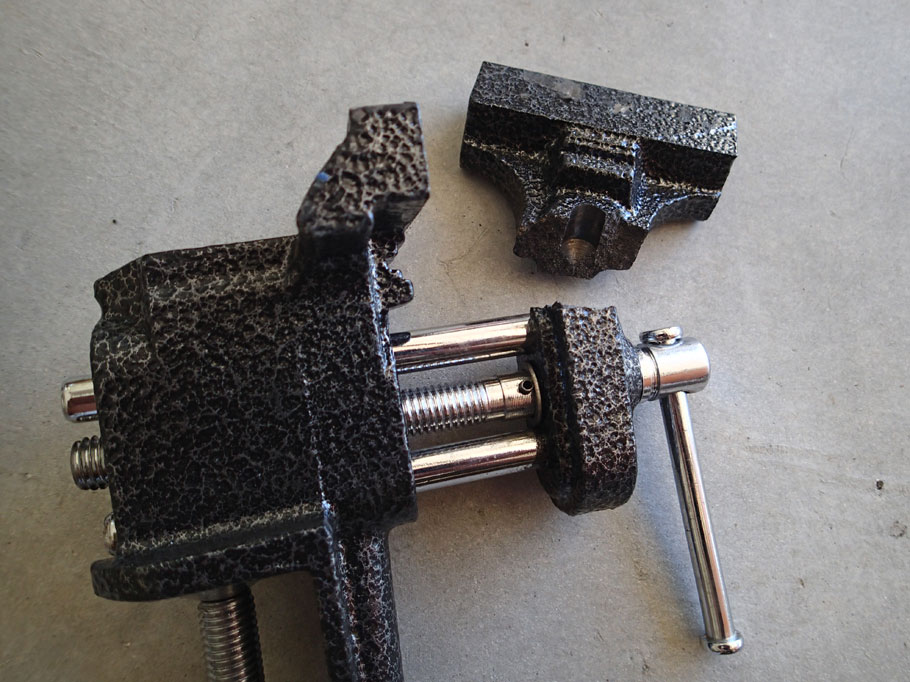

I’ve never felt good about spending a lot of money on tools. There have always been more important things to buy, like baby shoes and clothes. And since tools are fun to use, they must really be toys. And I’d feel guilty about buying myself toys. But now I have to take care of a diesel engine in the Vanagon, as well as one on the boat. Gonna need some new toys! (Oops, tools.)

The van we bought was loud and smoky. So smoky other motorists would flag us down to tell us we were on fire. So smoky a state trooper pulled me over. We really want an eco-friendly vehicle, so fixing the smoke became a high priority. When we got to Florida we put posts in a couple of online forums asking for advice.

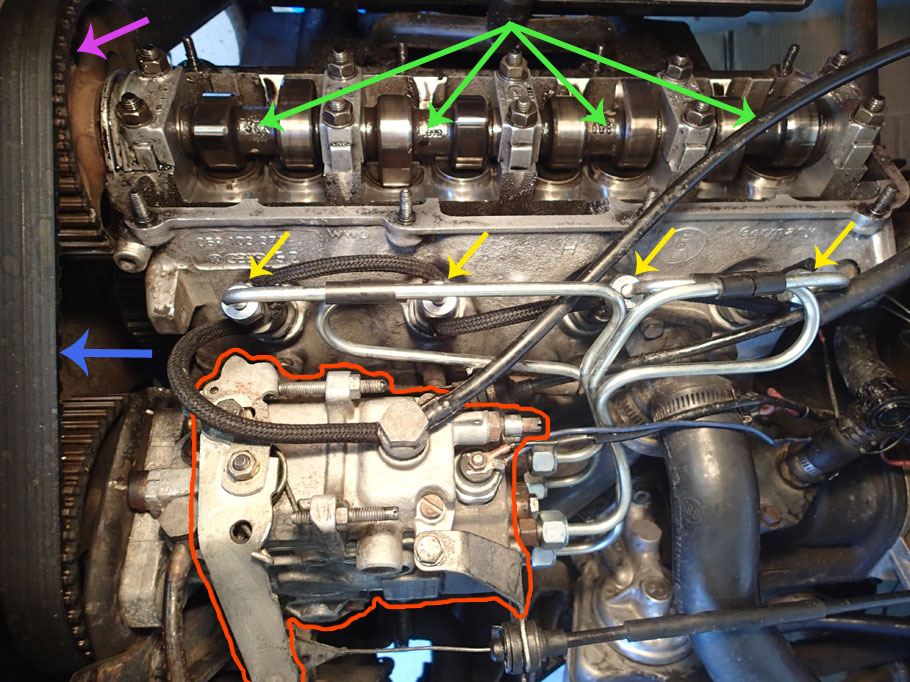

The VW diesel community had lots of suggestions: replace fuel injectors, check the compression, check the timing, and the valves. I’ve never done any of this stuff, so I spent a lot of time reading, reviewing diagrams in the shop manual, and just looking over the engine.

I shopped online for tools, trying to find the best values, and keeping in mind what we might need for the boat. I figured out a plan of attack, discussed it with Duwan, and started ordering stuff.

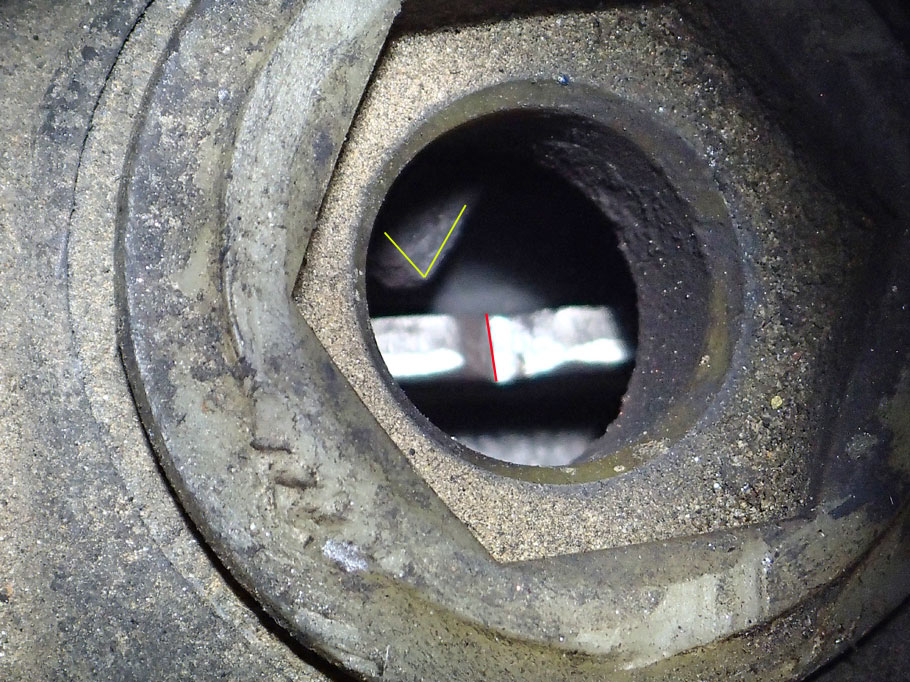

How do you figure out if you are getting less smoke in the exhaust? Holding a sheet of cardboard by the muffler while you rev the engine is OK. Making ‘before’ and ‘after’ videos of the engine running is also good. But it’s best to have your sweetheart follow you in another car with a camera mounted atop a tripod on her passenger-side floorboard. And when you get back home, what could be more entertaining than trying to decide which movie is smokier?

Replacing the fuel injectors helped a lot. Fixing the timing between the camshaft and crankshaft yielded an unexpected benefit. The engine had been gunning itself at random times earlier. It might start racing on its own as I coasted up to a red light. That stopped after the timing change.

I didn’t know that special motor oil was made for diesels. But changing out the oil and putting in new oil and fuel filters didn’t help much. Neither did putting in a fuel additive. My valve clearance is off, but just a tiny bit. That can’t be it.

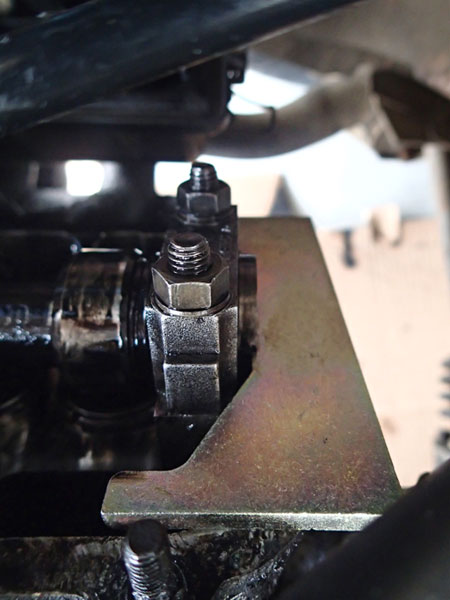

I experimented a lot with the fuel injection pump timing. This helped too, but the results were still unacceptable. This just had to be a fuel pump problem. What was I missing?

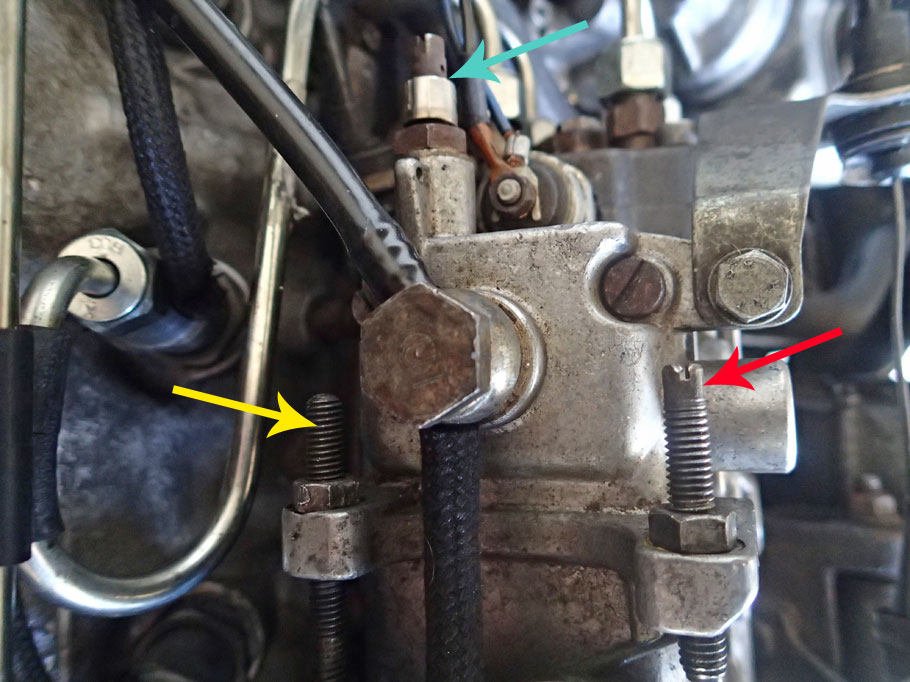

Well, I finally dug deep enough to find the ‘smoke’ adjustment screw. It’s not mentioned in the shop manual, and I can’t find an injection pump manual. But someone had a picture of it online.

Tweaking the smoke screw made a dramatic improvement. We are now road-worthy. (Please don’t tell Duwan it was that easy, though. She might want me to sell all my new toys.)